Core Structural Features

Vertical Layout: The base adopts a vertical column design, with the bottom fixed by a flange or anchor bolts. The top and middle sections support the motor body, enabling vertical installation without occupying horizontal space.

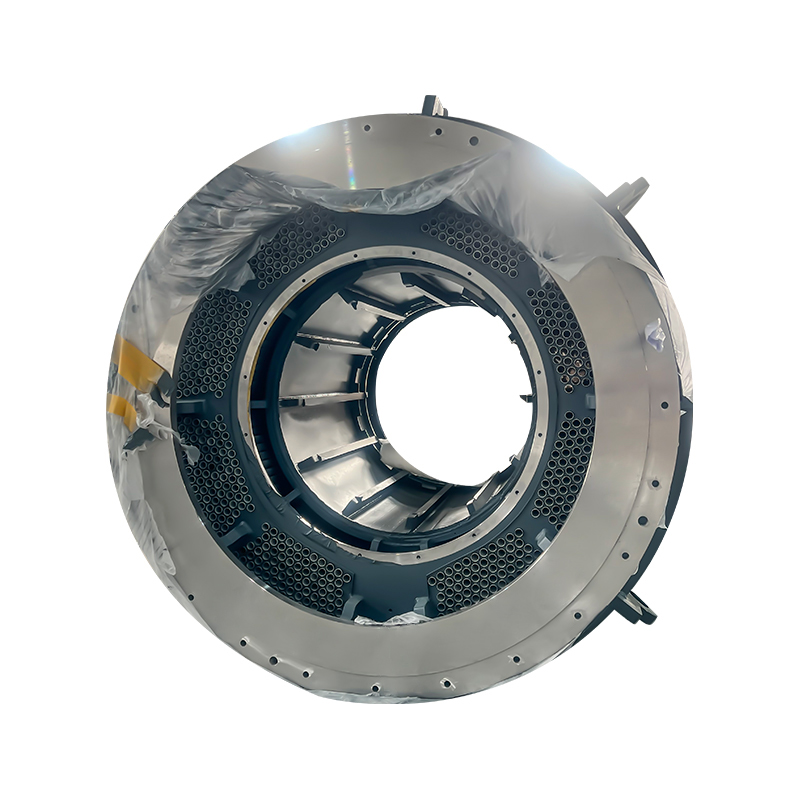

Pipe-Penetrating Core Structure: The middle or rear section of the base integrates a through-pipe channel, allowing the motor shaft, cooling pipes, or cables to pass through. This design provides both shaft system extension support and heat dissipation/flow diversion functionality.

Multi-Scene Adaptation Design: The inner diameter of the pipe can be customized. The base is equipped with shock-absorbing pads at the bottom and positioning pins at the top. Some marine models include waterproof sealing structures (IP65+ protection), making them suitable for humid and rough environments.

Integrated Heat Dissipation Optimization*: The pipe channel can serve as a water or air cooling conduit. It features heat dissipation fins that closely fit the motor housing, improving cooling efficiency by more than 25% compared to standard vertical bases.

Key Advantages

1. Maximized Space Efficiency

The vertical layout allows integration into confined vertical spaces, such as equipment mezzanines and beneath decks, reducing horizontal footprint by over 60%. This design is particularly suitable for densely arranged spaces such as engine rooms and machinery compartments.

The pipe-penetrating structure combines shaft system support and cable routing in one, eliminating the need for additional brackets and simplifying the overall layout.

2. Stable and Impact-Resistant Structure

The vertical column structure offers strong rigidity, with dual support provided by the bottom fixing and top positioning, ensuring excellent resistance to ship vibrations and industrial impacts.

The pipe penetration supports the shaft system at the middle, reducing deflection during the operation of long shafts and extending the lifespan of bearings and motors.

3. Efficient Multifunctional Integration

The pipe channel can accommodate water-cooling pipes, electrical wiring, and shaft extensions, eliminating the need for additional holes or installation of pipes. This improves installation efficiency by 40%. Marine models feature built-in waterproof seals in the pipe channels to prevent seawater or moisture intrusion, while industrial models are suitable for environments with dust and oil contamination, offering strong versatility.

4. Convenient Installation and Maintenance

The vertical lifting installation allows for quick positioning. The standardized base flange design enables two workers to complete the installation within half a day, without the need for complex adjustments.

The pipe channel makes it easy to service the shaft system and internal components. Some models offer top-access covers for maintenance, eliminating the need to disassemble the entire base.

en

en

русский

русский Deutsch

Deutsch