I. Basic Concept and Core Positioning

The Horizontal Aluminum Tube Cooling Machine Base is a composite support structure based on a horizontal configuration, integrating an aluminum-alloy cooling-pipe heat dissipation system. Its primary function is to provide stable support for the motor, while rapidly exporting operational heat through a circulating medium (water/coolant) inside the aluminum pipes, thereby realizing an integrated “support + cooling” solution. It is widely used in continuous-operation equipment scenarios where high-efficiency heat dissipation is required.

II. Core Structural Features

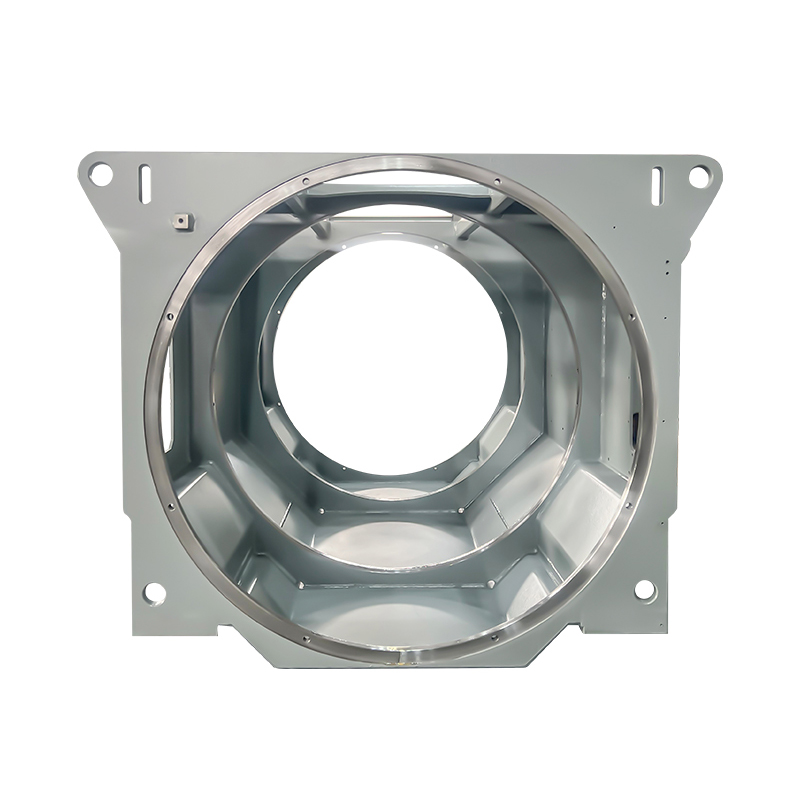

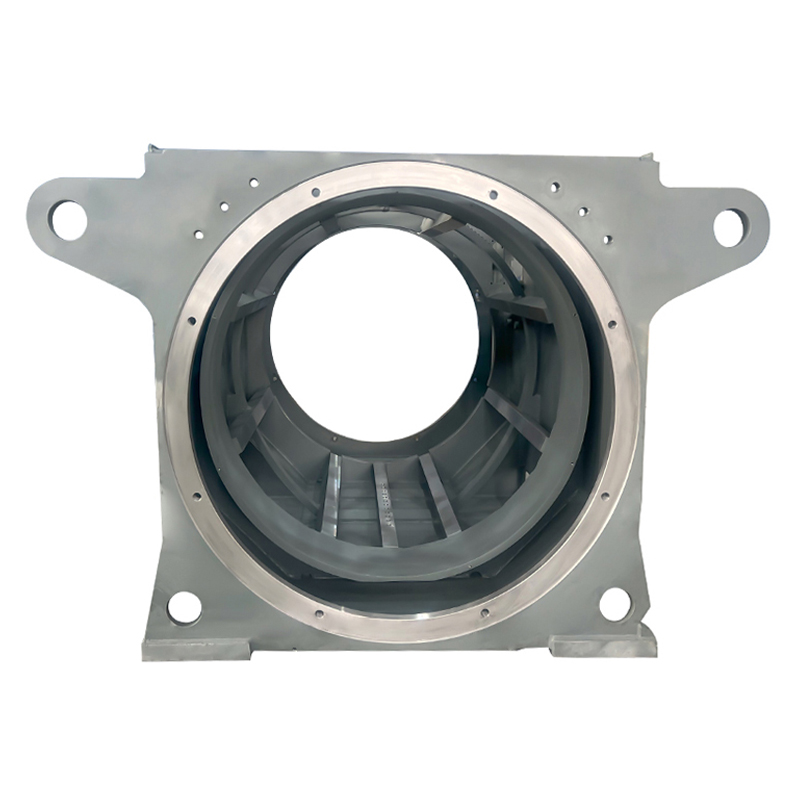

1. Main Structural Design

Horizontal support frame: Adopts a steel–aluminum composite structure, typically in a rectangular frame layout, with 2–4 sets of adjustable leveling feet at the bottom.

Aluminum-pipe cooling layer: Aluminum-alloy cooling pipes are embedded on the top and/or inside the frame, arranged in coil, manifold (parallel-pipe), or serpentine patterns, with a pipe spacing of 80–150 mm to maximize heat-transfer contact area.

Connection and sealing: The aluminum pipes are connected to the base via flange connections or compression fittings. Interfaces use nitrile rubber (NBR) seals, achieving IP54 protection, offering leak prevention and corrosion resistance.

Auxiliary structures: Equipped with medium inlet/outlet ports, a flow регулиation valve, and a temperature-monitoring interface. Some models integrate cooling fans to enhance convective heat transfer.

2. Core Cooling-System Design

Aluminum-pipe specifications: Pipe diameter φ16–φ50 mm, wall thickness 2–5 mm, thermal conductivity 201–237 W/(m·K) (approximately 4–5 times that of carbon steel), providing excellent heat dissipation performance.

Circulation channel: The cooling pipes form a closed-loop circuit that can be connected to an external cooling water tank or an industrial chiller, enabling reusable circulation of the medium.

3. Key Functional Advantages

High-efficiency heat dissipation: Aluminum pipes deliver far higher thermal conductivity than carbon steel or cast iron. Combined with the large-area contact enabled by the horizontal layout, heat dissipation efficiency improves by 60–80% compared with conventional machine bases, keeping operating temperature below 80°C.

Stable support: The horizontal frame plus multi-point adjustable leveling feet provides strong anti-tipping capability, suitable for horizontal equipment with speeds ≤ 3000 r/min.

Lightweight design: High aluminum content facilitates transport and installation, and reduces building/floor load requirements.

Corrosion-resistant and durable: Aluminum alloy naturally forms an oxide film, resisting moisture and oil contamination; service life is 3–5 years longer than ordinary steel bases.

Integrated system: No additional cooling brackets are required, saving installation space and simplifying system piping design.

en

en

русский

русский Deutsch

Deutsch