The motor mounting base is the primary load-bearing structural component that serves as the core foundation for motor installation. By connecting to the motor body and the mounting foundation (floor/ship hull/equipment frame), it provides critical assurance for stable motor operation. It is an essential component of motor systems in fields such as industrial production and marine propulsion.

I. Core Functions

Fixing and positioning: Securely fastens the motor via anchor bolts, flanges, and other structures to prevent displacement caused by vibration or load fluctuations during operation, ensuring coaxial alignment between the motor and the driven load (pumps, fans, shafting, etc.).

Vibration damping and buffering: Incorporates built-in vibration isolators (rubber/spring materials) or optimized structural design to absorb operating vibration, reduce vibration transmission to the mounting foundation, lower noise, and protect related equipment.

Leveling and alignment: Equipped with adjustable mounting feet, dowel pins, and similar components to facilitate on-site fine adjustment of motor levelness and verticality, ensuring shafting alignment accuracy and avoiding wear or failures due to installation deviations.

Application adaptability: Optimizes the structure based on the operating environment (industrial/marine, indoor/outdoor) and installation constraints (horizontal/vertical, confined/open), balancing requirements such as protection, heat dissipation, and space utilization.

II. Key Characteristics

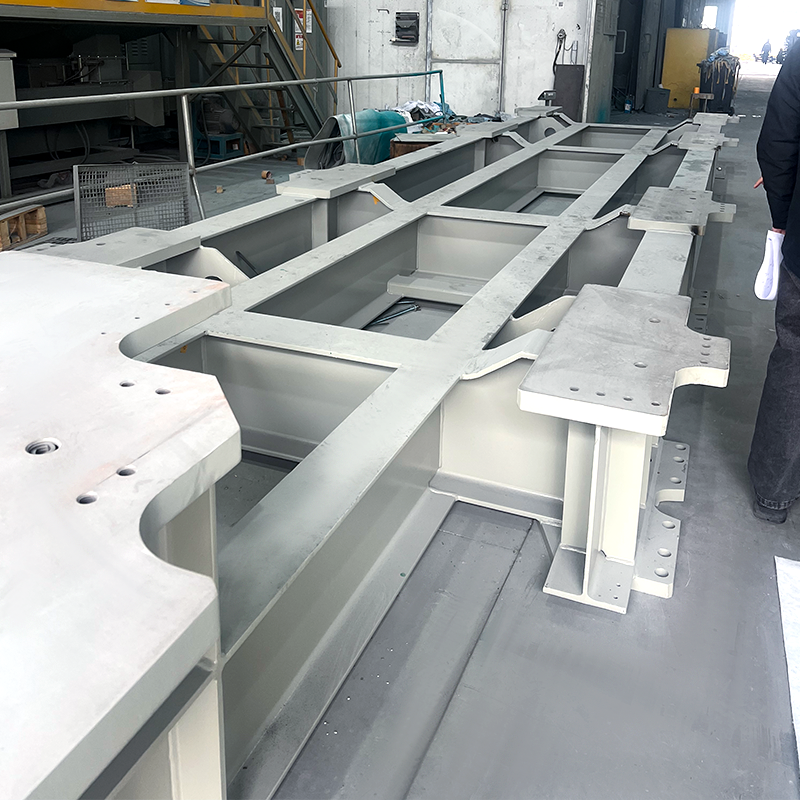

Material selection: In industrial applications, Q235B/Q345B steel plate is commonly used. For marine applications, salt-spray-resistant anti-corrosion steels such as Q345B/AH36 are selected. Some high-end versions use cast iron to enhance rigidity.

Structural design: Available in forms such as square, cylindrical, and split-clamp (shaft-hugging) types, with a core design objective of “uniform load distribution, high stiffness, and minimal deformation.”

Protection rating: Industrial versions typically meet IP54 (dust- and moisture-resistant), while marine/harsh-environment versions can reach IP65+ (waterproof and salt-spray-resistant) to satisfy different protection requirements.

Modular compatibility: The top surface often includes standardized flanges/locating pilots, enabling compatibility with motors of different power ratings and models, thereby reducing customization costs.

en

en

русский

русский Deutsch

Deutsch