Wuxi New Ruichi Technology Co., Ltd. is primarily engaged in the research, development, manufacturing, and sales services of electric punching and core products. Our products are mainly applied in new energy commercial vehicles, new energy non-road mobile machinery, wind power generation, industrial high-efficiency energy conservation and automation control, rail transit, and other fields.

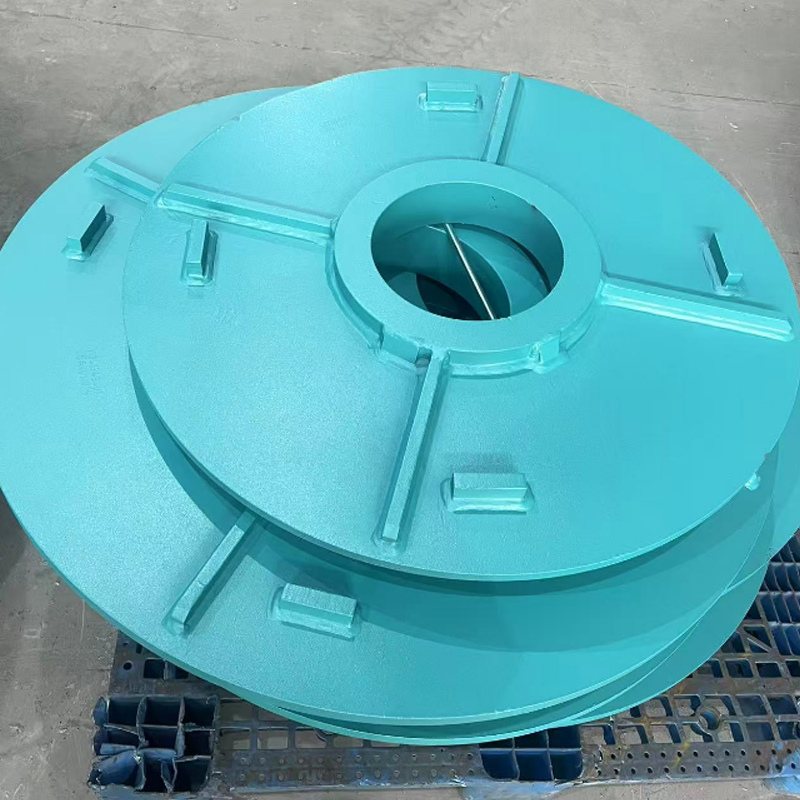

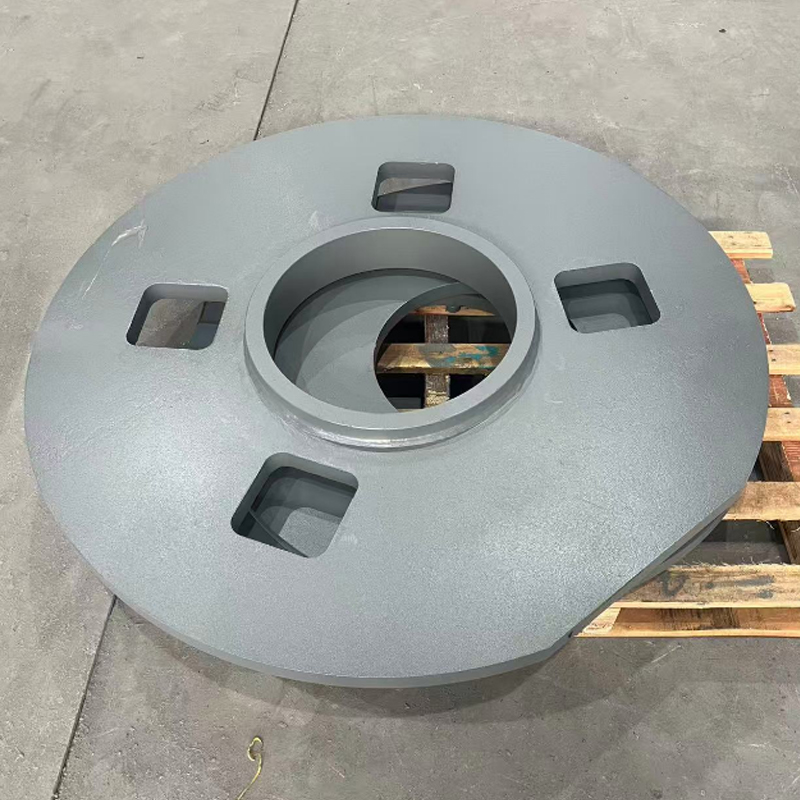

Wuxi Cailiang Machinery Co., Ltd., is a trusted manufacturer specializing in high-quality welded machine housings and end shells for wind power equipment and high-voltage industrial motors. Both companies have obtained ISO 9001, IATF 16949, and ISO 14001 certifications, and implement full-process quality monitoring using methods such as SPC (Statistical Process Control) and CMM (Coordinate Measuring Machine).

Looking ahead, they will continue to increase annual R&D investments, focusing on integrated innovation in "AI + smart manufacturing + green energy" to build robust technological barriers, ensure sustained product leadership, and create smarter, more efficient production workshops.

en

en

русский

русский Deutsch

Deutsch